Norco Manufacturing Blast Test

Norco recently designed hangar doors specifically for a blast test for an upcoming project. Details, along with photos and videos can be found below.

Norco Blast Test - Exterior View of Blast

The hangar door consisted of two separate leaves and was constructed of structural steel designed to resist blast. Norco designed the hangar door and performed a 1/3 scale live test as required by the contract as proof of design. The 1/3 scale test was intended to verify the performance of the hangar door and its ability to operate after an explosion. Blast loading for the test was specified as 12.6 psi and 82.1 psi-ms.

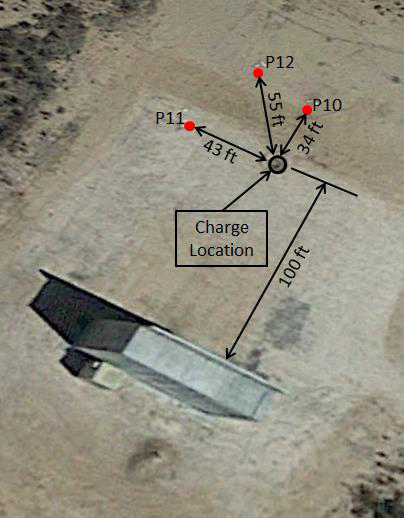

Test Configuration:

The hangar door consisted of two vertical spanning leaves installed in a rigid reinforced concrete reaction structure. A high-explosive charge was sited 100 feet perpendicular to the front of the reaction structure to generate reflected loads on the hangar door leaves. Five hundred pounds of Ammonium Nitrate Fuel Oil (ANFO) confined in a cardboard cylinder was used as the high-explosive material with one high explosive (HE) booster located in the cylinder to initiate detonation.

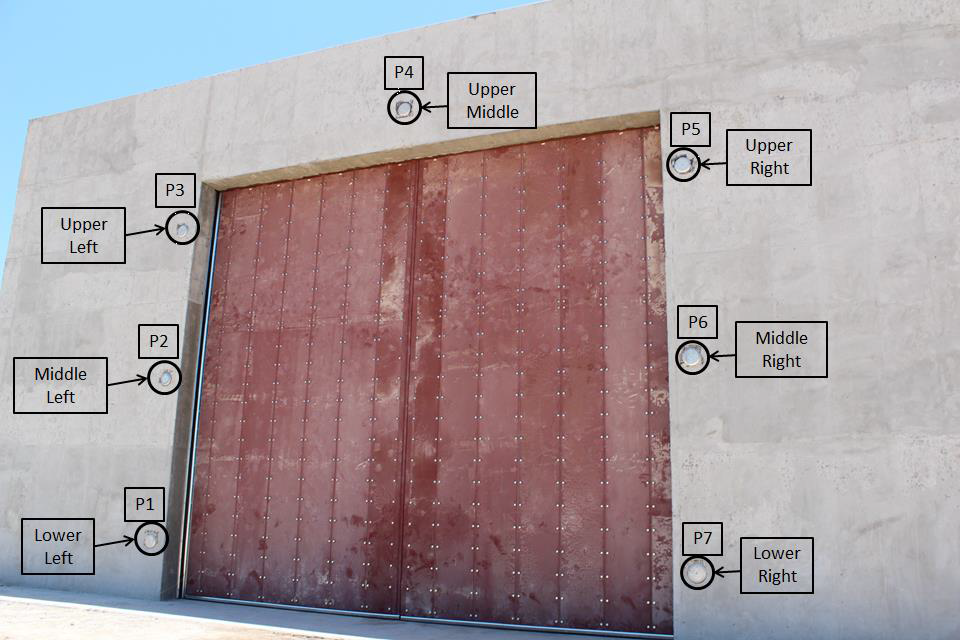

Dimensions of the steel door system were approximately 26’ wide by 23’ tall. The hangar doors were mounted in a reinforced concrete reaction structure with approximate dimensions of 58’ wide by 30’ tall by 14.3’ deep. An enclosed space in the reaction structure measuring 12’ deep, 23’ tall, and 55.67’ wide was located behind the door test article when in the closed position. Doors were restrained at the header by a door pocket in the concrete roof slab and a square steel stop bearing on a rail embedded in the floor of the reaction structure.

Data Acquisition & Instrumentation:

PCB 102A piezoelectric pressure gauges were used to measure the applied blast pressures and waveforms were recorded by a Yokagawa DL series digital scope sampling at a minimum of 1000 kHz.

Test Results:

The test door articles were subjected to a single blast event generated from a 500 lb charge of ANFO located 100’ directly in front of the reaction structure. Blast pressures, high-speed video, and HD video were captured.

General Observations & Conclusions:

The structural systems of the test doors withstood the blast event and incurred plastic/permanent deformation but were structurally sound. Both doors remained within the door pocket at the roof/ceiling juncture and on the rail tracks at the base of the doors. Doors were able to be opened manually post-test by forklift and/or with two or three persons pushing them.

A one-third scale HE test was successfully performed on the hangar doors designed by Norco Manufacturing. The structural systems of the door specimens sustained some permanent damage but were structurally intact after the test. The doors were operable manually post-tested. In layman's terms - we passed!

Norco Blast Test - Door Installation Norco Blast Test - After Blast Door Photo